Die casting is a metal casting technique that involves squeezing molten metal into a mold hole under high pressure. Two hardened tool steel dies, which have been machined into form and act similarly to an injection mold throughout the operation, use these to construct the mold cavity.

There are many aluminum die-casting manufacturers accessible around the globe. We’ve chosen the top twenty die casting firms from among them discussed in the following.

Carteret Die-Casting Corporation

Carteret’s automated production management system records client orders from start to finish and, upon request, can give real-time order progress information. However, the headquarters of this company is at 74 Veronica Ave, Somerset, NJ 08873, United States.

Their latest facility expansion allows them to handle flexible shipping plans, including J.I.T., CONBON, ship-to-stock, and blanket contracts with repeated deliveries also.

Carteret’s Quality Management System has been ISO 9001 accredited. From initial sample through production runs, their highly qualified quality assurance staff. In this case, they use state-of-the-art measurement equipment, sophisticated quality planning, and statistical quality assurance procedures to manufacture the products for their client’s specifications.

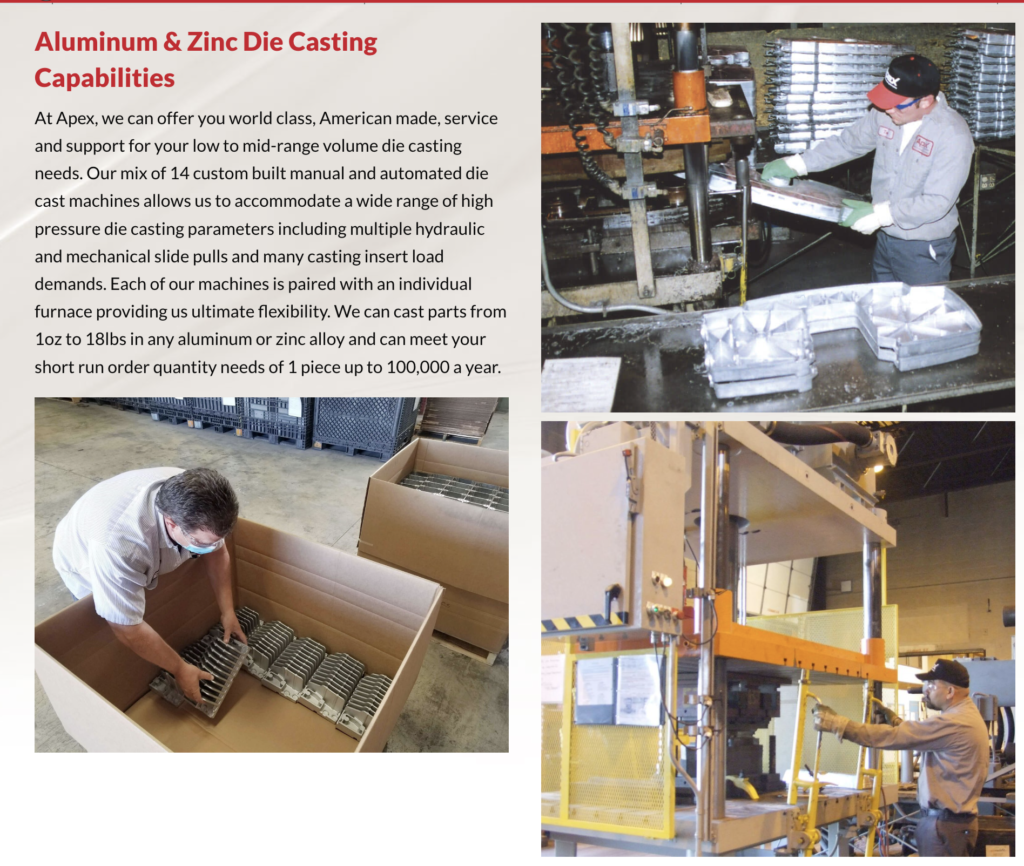

Apex Aluminum Die Casting Company

Apex Aluminum Die Casting was established in 1980, located at 8877 Sherry Dr, Piqua, OH 45356, United States, and has remained a family-owned and run company. They are delighted to service a diverse range of sectors around the country.

Apex aluminum die-casting manufacturer provides world-class, American-made service and support for low to mid-volume die casting requirements. In particular, they can support a broad range of high-pressure diecasting characteristics, including numerous hydraulic and mechanical slide pulls and various casting insert load needs, thanks to their 14 custom-built manual and automated die cast machines.

A & B Die Casting

Ben Dathe moved to the United States from Dresden, Germany, in 1924 to pursue his ambition of establishing his tool and die firm. He began his agency and die apprenticeship in the former nation when he was 14 years old.

Recently, this company’s headquarter address is 900 Alfred Nobel Dr, Hercules, CA 94547, United States.

Ben proudly opened the doors to Benda Tool in Berkeley, California, twenty-one years later. He derived the name of his firm from the first five letters of his name. In this period, Benda Tool quickly acquired a reputation for personalized service and high-quality manufacture.

Ben saw the possibilities of die casting early on. Ben founded A&B Die Casting in response to the encouragement of his most significant client and become one the most popular die casting manufacturers in the world. Benda Tool and A&B Die Casting were combined in a new 5000 sq. ft. factory when Ben’s son, Bob, joined the company with a degree in mechanical engineering.

American Precision Die Casting

In June of 2005, American Precision Die Casting established its production system, locating at 100 American Way, Cuba, MO 65453, United States.

American Precision Die Casting (APDC) is a privately-held producer of diecast components produced from aluminum alloy 380 situated in Cuba, Missouri, approximately 70 miles southwest of St. Louis, right off Interstate 44.

The manufacturing plant is 26,600 square feet in size and sits on five acres of land, with plenty of potential for future growth. APDC operates three shifts, 24 hours a day, Monday through Friday, with a devoted crew of 65 individuals (and Saturdays when needed).

Aluminum Die Casting Co Inc

Aluminum Die Casting Co., Inc., founded in 1950, is a third-generation family-owned and run manufacturing company. With Steve Bennett as President and Michael Bennett as Vice President/General Manager, they dedicated the Bennetts to continual improvement, cost reduction, on-time delivery, and complete client satisfaction.

The address of this company is 10775 San Sevaine Way, Mira Loma, CA 91752, United States.

After more than 50 years, we now have a 35,000 square foot building in Mira Loma, California. They chose this position deliberately to be handy for all of our customers, suppliers, and staff and be near Ontario International Airport.

A.D.C. specializes in short or medium-run needs (50 to 100,000). They are flexible enough to handle your accelerated tooling and production complete to your solid model and specifications.

KenWalt Die Casting Company

KenWalt Die Casting Company is an ISO 9001-certified and ITAR-registered American die casting company that produces high-quality aluminum and zinc die castings in the United States. You can meet them at 8719 Bradley Ave, Sun Valley, CA 91352, United States.

Automotive castings, aerospace castings, medical castings, industrial castings, computer castings, solar castings, telecommunications castings, and many more industries have used aluminum and zinc castings for over 50 years.

The Pressure Die Casting Process produces metal diecast items by forcing molten aluminum and zinc metal alloys into steel diecast dies or diecast molds in die casting equipment.

Midland Pressure Diecasting Ltd

Pressure in the Midlands Diecasting is one of the most rapidly expanding diecasting foundries in the United Kingdom. The address is Ashmore Lake Way, Willenhall WV12 4LF, United Kingdom.

The firm has developed from a small start-up in 2000 to the multi-million-pound turnover S.M.E. it is today, operating from a 50,000 square meter factory on a 5-acre location with room for expansion.

Year after year, the firm has worked hard to expand and provide superior value-added services to our clients, ranging from die castings to machined castings to painted and plated castings supplied completed.

A.M.E Pressure Die Casting Ltd

A.M.E is a major high-pressure precision zinc maker in the United Kingdom. They have been delivering the best quality Zinc die castings to almost all sectors globally since the proprietor founded them in the heart of industry in the West Midlands.

Their headquarter address is at Siddons Factory Estate, Howard St, West Bromwich B70 0SU, United Kingdom.

Their fully automated fast-cycling hot chamber die casting cells can manufacture even the most intricate castings to the tightest tolerances and with the most significant level of polish.

Through a program of continuous improvement, devoted employees, and investment growth into new technologies, they aspire to exceed our customers’ expectations for Quality and Service in the items they deliver.

Kemlows Diecasting Product

Kemlows Die casting Products Ltd is a company that specializes in diecasting, locating at Charlton Mead Ln, Hoddesdon EN11 0HB, United Kingdom.

However, Charles Kempster and William Lowe started Kemlows Diecasting Products Ltd in 1946 to produce diecast miniature toys from their London headquarters.

From its initial client base, the firm swiftly expanded into engineered components and the automobile industry. After two significant expansions, a new purpose-built facility in Hoddesdon, Hertfordshire, was commissioned and erected in 1974, where the firm is still situated today.

The firm has grown in terms of both technology and client base throughout the years. The Teoli family bought the firm in 2001. Since then, continued efficiency has shifted the manufacturing emphasis towards more significant casting projects spanning all sectors and casting users, complementing the current aluminum and zinc customer base, thanks to constant improvements and capital investment.

Haworth Castings Ltd

Haworth Castings is a foundry and machining center in Romsey and Basingstoke, Hampshire, specializing in aluminum and copper castings. Whereas, the headquarter address is Budds Ln, Romsey SO51 0HA, United Kingdom.

Lachlan Birds, who took over as Managing Director from Andrew Haworth in June 2019, leads the company.

In this case, they specialize in offering a completely owned and managed single-source solution for their clients by creating machined, tested, and completed sand castings and gravity die castings for the military, aviation, marine, medical, energy, automotive safety-critical sectors.

Socometa

Socometa is a fictional character created by Socometa, locating at 5 Rue de l’Ouillette, 16500 Confolens, France. In this case, the company can cast all of the components you need in Aluminum, Bronze, or Copper Alloy using gravity, etc.

They do, however, have expertise in the following areas: Cored parts: our SHALCO machines enable the production of cores for non-moldable forms. Large-sized components: Our Shell molding machines and Low-Pressure molding machines can mold large-sized pieces.

Overmolded parts using steel, stainless steel, and brass inserts to strengthen certain regions, incorporate fasteners, and make joins. In this case, they use parts with over-molded stainless steel coils to achieve integrated cooling or heating circuits. Besides, Cast and machined items with strict tolerances, technical items with complicated forms

Falsimagne SA Fonderie

Falsimagne is a family-owned and operated foundry at 293 Rue de Saint-Valéry, 80460 Woignarue, France. In particular, the address is Picardy Maritime, in the Somme department, in the center of the Vimeu industrial basin. However, Georges Falsimagne founded this company in 1948.

Falsimagne Foundry and its partners address the most challenging Zamak, cupro aluminum, and aluminum alloy foundry issues. With over 1,200 tonnes of non-ferrous metals handled each year, ever more efficient production methods and knowledge of foundry technologies.

INOXYDA

INOXYDA is an acronym for “inoxyde”. This company is a public limited company based in Petit-Quevilly, Rouen suburbs, Paris.

This company established itself in 1924 as the Forges & Foundry of High Resistance Alloys (FFAHR). Its expertise, which has accumulated since its inception, is in casting copper alloys.

Under the trademark INOXYDA, the business was the first to cast cupro-aluminum, commonly known as aluminum bronze.

Cupro-remarkable aluminum’s resistance to marine corrosion allowed the business to engage with the French Navy. Electricité De France quickly adopted this alloy to use tidal and thermal power plants and nuclear power plants.

Druckguss Westfalen GmbH & Co KG

Druckguss is one of the most renowned companies based in Westfalen, Germany. It is one of the most modern and adaptable aluminum die casting foundries in the world. Their objective has always been complete client satisfaction since they first opened their doors in 1964.

Since 2016, we’ve also offered full-service zinc die casting via our sister firm, Druckguss Westfalen Behringer.

They operate a highly advanced machine park with fully automated die casting cells featuring real-time shot control in Geseke. In particular, at their sister company in Velbert, they operate a full-service die casting foundry with an extensive and advanced portfolio.

Customers in various sectors benefit from their services, including automotive and electrical engineering, sanitation, mechanical, etc. Their cutting-edge machining technology makes even the most complicated and technically complex goods simple to manufacture. Druckguss Westfalen is also your go-to foundry for creative solutions requiring special finishing techniques.

The wolf group

The Wolf Group is a company that specializes in Germany. The family business developed itself in Regensburg in 1933 by the present owner’s grandfather under “Elektro Wolf.” This company stumbled upon zinc die casting by happenstance.

The inclusion of aluminum accelerated the development of the Regensburg diecasting factory from 1977 to a constantly expanding foundry. The Wolf Group manufactures 5% zinc diecast components for the world automotive and electrical sectors, in addition to aluminum casting. The medium-sized business is now in its third generation and remains entirely family-owned.

Jordan Reflectors GmbH & Co. K.G.

Jordan, a classic corporation, established itself in Wuppertal in 1924, located at Schneiderstraße 76, 40764 Langenfeld (Rheinland), Germany. From this original manufacturing facility, the Jordan Group has grown into what it is today.

In this case, Jordan views itself as an innovative full-service partner to the lighting sector as a long-standing O.E.M. supplier.

However, Jordan now offers its customers more service and know-how in the fields of surface technology, aluminum die-casting.

AUER GUSS GmbH

This company is a worldwide society and complies with relevant rules and regulations in the Czech Republic. Whereas, the address of the center is Mundfeldweg 11, 92224 Amberg, Germany.

They believe that company success, law and order compliance, employee accountability, and environmentally responsible treatment are all intertwined. In this case, men and women of all nationalities work together amicably and respectfully in our organization.

E.M.P. Technology Co., Ltd.

In 2004, E.M.P. Die Casting developed their production lines. In contrast, their facility is 50,000 square meters, and they employ 500 engineers and support employees. The location of this company is at NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China.

In addition, The automotive, manufacturing, industrial, telecom, and electronics sectors are their primary customers.

Their dedication to continual research and development in bespoke aluminum die casting has resulted in over 17 patents and a growing client base in over 25 countries around the globe.

Die Casting Newcast

The center address of this company is Yesvanpur Surburb, Phase 3, Peenya, Bengaluru, Karnataka 560058, India.

Since 1998, they have been producing and exporting high-quality die casting components for India and Europe.

They produce: Pressure Die Castings up to 3 kg in weight, made from Aluminum Alloys A.D.C. and L.M. series, Zinc Alloys Zamak-3 and Zamak-5, and additional types as the required client.

Indian Diecasting Industries

Indian Diecasting Industries, based in Aligarh, Uttar Pradesh, established itself in 1964 and is one of the top producers of Aluminum Die Cast Components, Zinc Die Cast Components, Die Casting Moulds, and other products. However, the company manufactures the products from high-quality raw materials purchased from reputable suppliers in the industry.

Besides, these are available in various parameters, and they may modify to meet the needs of our customers.

Their company has a well-developed infrastructure facility divided into numerous production, warehousing, packaging, and in-house quality testing. A group of highly skilled individuals overseen these units that allow us to provide an unrivaled selection of goods to our customers while maintaining high levels of accuracy. Furthermore, it is our goal to provide high-quality items to our customers.

Conclusion

The twenty die casting companies listed above are among the best in the world. Therefore, we conducted extensive research on these industrial companies’ websites, Facebook pages, and YouTube channels to get all relevant information.

This article will assist you in locating a suitable manufacturing firm in your area. In addition, It will help you in doing in-depth research.