Are you in the market for a Laser marking machine? But feeling overwhelmed by the variety of options available? Choosing the right Laser marking machines is crucial for your business. As it can impact your productivity and profitability. To help you make an informed decision. we’ve compared five popular laser machines on the market today. From the versatile CO2 laser to the high-powered fiber laser. Each machine has its own unique set of features and capabilities. By understanding what each Laser marking machine has to offer. You can choose the one that best fits your needs and helps you achieve your business goals. So, let’s dive into our comparison of the top five laser machines. But before starting here’s a quick overview of how laser machines work. what are their technical features, and how to choose the best one?

Laser Marking Machines. How do they work?

At the heart of every laser marking machine is a high-powered laser beam. which is directed onto the material being marked. The beam creates a permanent mark by removing material or by causing a chemical reaction. which changes the color of the material. This process is incredibly precise. Allowing for the creation of even the most intricate designs and patterns. Laser marking machines come in a variety of sizes and configurations. From compact desktop models to large industrial machines that can mark many parts. They can be used with a wide variety of materials, including metals, ceramics, and more. They are also compatible with a range of marking techniques. Ranging from engraving, annealing, foaming, and more.

If you are looking for a reliable and efficient way to mark your products. A laser marking machine may be the perfect solution. With their advanced technology and versatile capabilities. They can help you create the high-quality marks you need to meet your business needs.

Here we bring the Top 6 Best Laser marking machines, available in the market in 2023. This detailed comparison will assist you in choosing the best as per your needs.

The HI-Speed MOPA Fiber Laser Marking Machines:

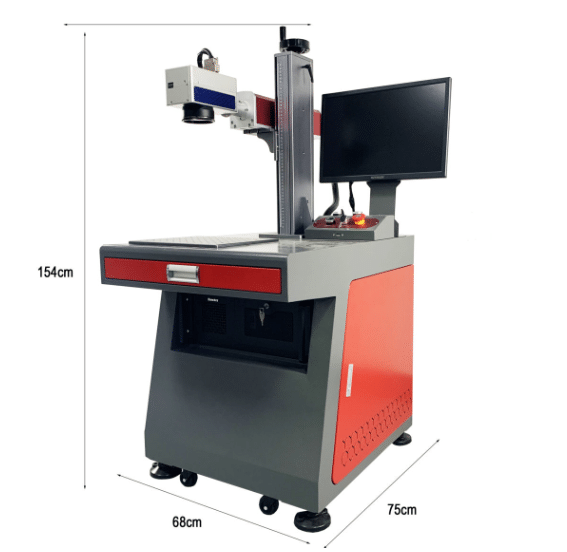

The HI-Speed MOPA Fiber Laser Marking Machine is available in 20W, 30W, 60W, and 100W options. This machine offers a unique combination of power and precision. Making it a top choice for a wide range of marking applications.

At its core, the Hi-Speed MOPA Fiber Laser Machine features a high-powered laser. Which can mark a variety of materials with incredible speed and accuracy. With its MOPA technology. This machine offers greater control over the laser pulse duration. Which allows for more precise marking on even the most sensitive materials.

Besides its advanced technology. Hi-Speed MOPA Fiber Laser Marking Machine also boasts a user-friendly interface. Which makes it easy to set up and operate. It also features a compact design, allowing it to fit seamlessly into any workspace.

Whether you’re marking metal, plastic, or other materials. Hi-Speed MOPA Fiber Laser Marking Machine delivers exceptional results. Its versatility and reliability make it a valuable addition to any business.

Technical Specifications:

Laser source:

- Type: MOPA fiber laser

- Wavelength: 1064 nm

- Power: 20W/30W/50W/100W (depending on model)

- Pulse duration: 4-200 ns

- Pulse frequency: 1-500 kHz

- Beam quality: M²<1.5

Marking area:

- Maximum marking area: 110mm x 110mm (larger areas available depending on model)

- Marking speed: Up to 7000mm/s

- Minimum line width: 0.01mm

Mechanical specifications:

- Marking head: Galvanometer scanning head

- Focal length: 160mm (standard)

- Positioning accuracy: ±0.002mm

- Cooling: Air cooling or water cooling (depending on model)

- Power supply: AC 110V/220V ± 10%, 50/60Hz

Software:

- Compatible file formats: PLT, DXF, AI, DST, BMP, JPG, JPEG, PNG, GIF, TGA, TIFF, CDR, CMX, etc.

- Operating system: Windows 7, 8, 10

- Software functions: Text, graphics, logos, barcodes, serial numbers, date codes, etc.

Optional accessories:

- Rotary device for marking cylindrical objects

- Autofocus system for automatic height adjustment

- Vision system for precise alignment

- Marking on the fly system for continuous marking of moving objects

- Integrated fume extraction system

HANTECCNC Fiber Handheld Laser Marking Machines:

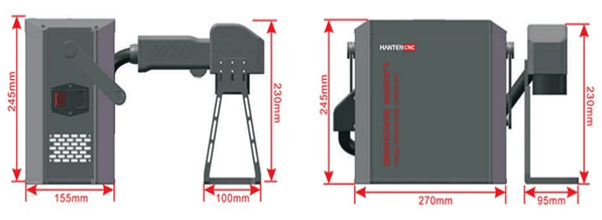

The 20W and 30W Fiber Handheld Laser Marking Machines are powerful yet compact machines. That delivers exceptional marking capabilities. These machines feature a high-powered laser beam. Which can mark a variety of materials with precision and accuracy.

The Fiber Handheld Laser Marking Machines are designed for easy portability and use. Making them an ideal choice for on-the-go marking applications. Their handheld design allows operators to move the machine to the part to be marked. Rather than having to move the part to the machine.

These machines feature a user-friendly interface that makes it easy to set up and operate. They also offer a range of marking capabilities, including text, logos, barcodes, and more. With their high precision and speed. They are an excellent choice for a variety of industries, including automotive, aerospace, medical, and more.

The Fiber Handheld Laser Marking Machines are also built to last. They feature a durable design that can withstand harsh working environments. Making them a reliable choice for businesses of all sizes.

Technical specifications:

Laser source:

- Type: Fiber laser

- Wavelength: 1064 nm

- Power: 20W/30W/50W (depending on model)

- Pulse frequency: 20-80 kHz

- Beam quality: M²<1.5

Marking area:

- Maximum marking area: 110mm x 110mm (depending on model)

- Marking speed: Up to 12000mm/s (depending on model)

- Minimum line width: 0.01mm

Mechanical specifications:

- Marking head: Handheld marking head

- Focal length: 160mm (standard)

- Positioning accuracy: ±0.01mm

- Cooling: Air cooling

- Power supply: AC 110V/220V ± 10%, 50/60Hz

Software:

- Compatible file formats: PLT, DXF, AI, DST, BMP, JPG, JPEG, PNG, GIF, TGA, TIFF, CDR, CMX, etc.

- Operating system: Windows 7, 8, 10

- Software functions: Text, graphics, logos, barcodes, serial numbers, date codes, etc.

Optional accessories:

- Rotary device for marking cylindrical objects

- Autofocus system for automatic height adjustment

- Integrated fume extraction system

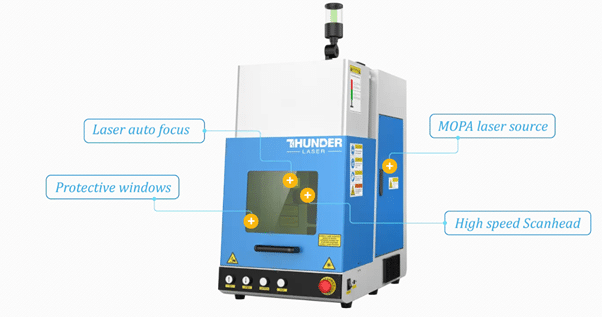

Aurora Thunder Laser Marking Machines:

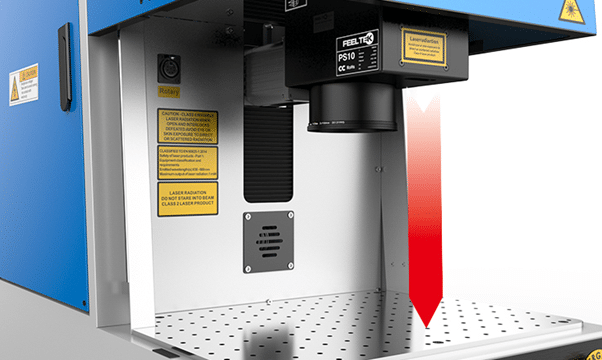

The Aurora Thunder Laser marking machine is highly versatile and efficient. The machine uses a 1064nm laser wavelength. which is highly effective for marking a wide range of materials. Its high-quality fiber laser source is energy-efficient and has a long service life. Which ensures that it can operate for extended periods, without the need for frequent maintenance.

The machine’s large marking area of 110mm x 110mm, combined with its fast marking speed of up to 7000mm/s. which makes it highly suitable for high-volume production environments. Its advanced control system is user-friendly and intuitive. Which allows for precise and accurate marking of intricate designs and patterns.

Additionally, the machine is equipped with a high-quality cooling system. Which prevents overheating of the laser source. Ensuring reliable and consistent marking results. Its technical specifications make it an ideal tool for a wide range of applications. Specifically for industrial manufacturing, art and design, and more.

Technical specifications :

The technical specifications of the Aurora Thunder Laser marking machine may vary depending on the specific model and configuration. However, here are some general specifications that you can expect:

- Laser type: Fiber laser

- Laser power: 20W/30W/50W/60W/100W

- Laser wavelength: 1064nm

- Marking speed: Up to 7000mm/s

- Marking area: 110mm x 110mm, 175mm x 175mm, 220mm x 220mm, or custom sizes available

- Minimum line width: 0.01mm

- Minimum character size: 0.15mm

- Marking depth: Up to 1.2mm (depending on material and laser power)

- Cooling system: Air cooling or water cooling (depending on laser power)

- Power supply: AC 220V 50/60Hz

- Supported file formats: PLT, PCX, DXF, BMP, etc.

- Compatible operating systems: Windows 7/8/10

- Interface: USB, Ethernet

ATOMSTACK Portable Laser Engraver:

The ATOMSTACK Portable Laser Engraver. A high-powered machine that offers exceptional cutting and engraving capabilities. This machine features a 40W laser cutter and engraver. That can work with a variety of materials, including wood and metal. It also has a 5.5W output power that can mark dog tags with precision.

One of the standout features of the Laser Engraver is its compact and portable design. It is 85% pre-assembled, making it easy to set up and use. It also features a fine engraving area of 200x200mm. ultimately allowing for precise and detailed engravings.

The ATOMSTACK Portable Laser marking machines Engraver is designed for DIY enthusiasts and hobbyists. As well as small businesses. It offers a range of marking and engraving capabilities. Including text, logos, graphics, and more. With its high precision and speed. It is an excellent choice for a wide range of applications. especially for jewelry making, model building, and more.

Technical Specifications:

Laser source:

- Type: Semiconductor laser

- Wavelength: 445-450nm

- Power: 5.5W/7W (depending on model)

- Pulse frequency: 10-60 Hz

- Beam divergence: 0.15-0.2mrad

Engraving area:

- Maximum engraving area: 140mm x 200mm (depending on model)

- Engraving speed: Up to 3000mm/min

- Engraving depth: Up to 1mm (depending on material)

Mechanical specifications of Atomstac Laser Marking Machines :

- Engraving head: Fixed focus laser head

- Focal length: 50mm

- Positioning accuracy: ±0.01mm

- Cooling: Air cooling

- Power supply: DC 12V/2A

Software:

- Compatible file formats: JPG, PNG, BMP, GIF, ICO, CUR, etc.

- Operating system: Windows 7, 8, 10

- Software functions: Text, graphics, logos, images, etc.

Other specifications:

- Supported materials: Wood, bamboo, paper, plastic, leather, rubber, foam, etc.

- Supported languages: English, Chinese, Japanese, German, Italian, Portuguese, Spanish, etc.

- Dimensions: 200mm x 190mm x 45mm

- Weight: 1.5kg

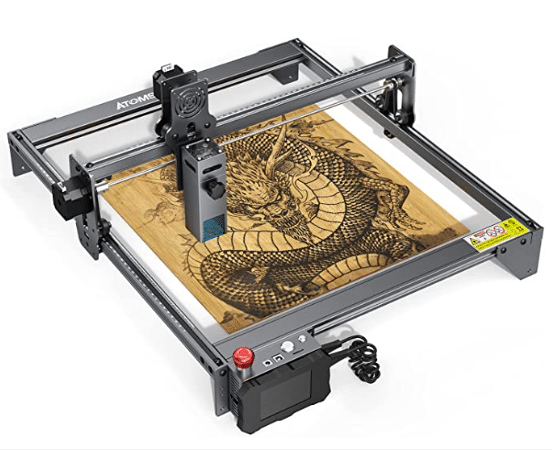

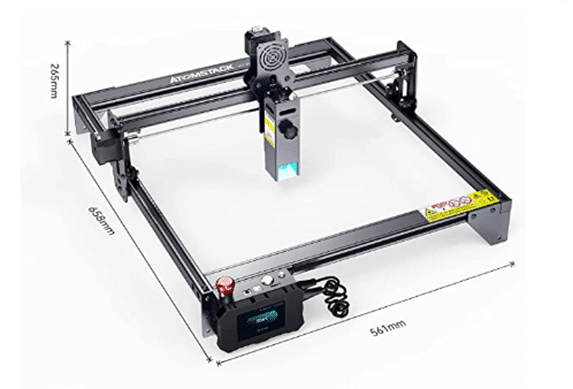

ATOMSTACK X7 Pro is a powerful fixed focus:

The ATOMSTACK X7 Pro is a powerful laser engraver that is designed to provide precise results. Its 20W laser module provides the machine with high-powered engraving capabilities. Making it ideal for use with a variety of materials. The machine can engrave wood, leather, acrylic, and more with high precision and speed.

The ATOMSTACK X7 Pro has a large engraving area, measuring 255 x 440mm. This provides ample space for a variety of materials and designs. Making it ideal for a wide range of applications. The machine’s fixed focus feature allows for easy and precise engraving. without the need for manual adjustments.

The ATOMSTACK X7 Pro is also equipped with an advanced cooling system. which ensures that the machine can operate for extended periods without overheating. The machine’s control system is also highly intuitive. Allowing for easy setup and operation.

The ATOMSTACK X7 Pro is a powerful and efficient laser engraver. Its high-powered laser module has a large engraving area. And fixed focus feature makes it a versatile tool for a wide range of materials and designs.

Technical Specifications:

Laser source:

- Type: Semiconductor laser

- Wavelength: 445-450nm

- Power: 7W/20W/40W (depending on model)

- Pulse frequency: 10-60 Hz

- Beam divergence: 0.15-0.2mrad

Engraving area:

- Maximum engraving area: 200mm x 200mm (depending on model)

- Engraving speed: Up to 8000mm/min

- Engraving depth: Up to 5mm (depending on material)

Mechanical specifications of Atomstac X7 Laser Marking Machines:

- Engraving head: Fixed focus laser head

- Focal length: 50mm

- Positioning accuracy: ±0.01mm

- Cooling: Air cooling

- Power supply: AC 110V/220V ± 10%, 50/60Hz

Software:

- Compatible file formats: JPG, PNG, BMP, GIF, ICO, CUR, etc.

- Operating system: Windows 7, 8, 10; Mac OS X; Linux

- Software functions: Text, graphics, logos, images, etc.

Other specifications:

- Supported materials: Wood, bamboo, paper, plastic, leather, rubber, foam, etc.

- Supported languages: English, Chinese, Japanese, German, Italian, Portuguese, Spanish, etc.

- Dimensions: 400mm x 330mm x 180mm

- Weight: 4.5kg

Optional accessories:

- Rotary device for marking cylindrical objects

- Autofocus system for automatic height adjustment

- Safety goggles for eye protection

LaserPecker 3 Deluxe Laser Engraver:

The LaserPecker 3 Deluxe Laser Engraver is a portable and efficient laser engraver. It is designed to provide high-quality results. The machine is equipped with a 450nm blue laser. which has a power output of 4500mW, providing high-powered engraving capabilities. This makes it suitable for use with a variety of materials, including wood, leather, acrylic, and more.

The LaserPecker 3 Deluxe is also highly portable, making it ideal for use on the go. The machine has a compact and lightweight design, and can be easily carried in a backpack or bag. This makes it perfect for artists, makers, and hobbyists who need a portable engraving solution.

The LaserPecker 3 Deluxe also features an advanced control system that is easy to use and intuitive. The machine connects to a mobile app, which allows users to easily create and edit designs. The app also provides access to a variety of engraving patterns and designs, making it easy to get started with engraving right away.

Technical Specifications:

Laser source:

- Type: Semiconductor laser

- Wavelength: 450nm

- Power: 4W

- Beam diameter: 0.06mm

Engraving area:

- Maximum engraving area: 100mm x 100mm

- Engraving speed: Up to 1500mm/min

- Engraving depth: Up to 1mm (depending on material)

Mechanical specifications:

- Engraving head: Fixed focus laser head

- Focal length: 16mm

- Positioning accuracy: ±0.01mm

- Cooling: Air cooling

- Power supply: DC 5V/2A

Software:

- Compatible file formats: BMP, JPG, PNG, G-code, etc.

- Operating system: Android, iOS, Windows

- Software functions: Text, graphics, logos, images, etc.

Other specifications:

- Supported materials: Wood, bamboo, paper, leather, rubber, plastics, etc.

- Dimensions: 65mm x 61mm x 53mm

- Weight: 190g

A Detail Technical Comparison of the Top 6 Laser Marking Machines:

| Machine Name | Technical Features | Price Range (USD) | Laser Power | Engraving Area | Compatible Materials |

| Hi-Speed MOPA Fiber Laser Marking Machine | – MOPA fiber laser technology, Adjustable pulse width, High-speed marking, Long service life | $4,000 – $12,000 | 20W – 120W | 110mm x 110mm | Metals, plastics, ceramics, and more |

| The 20W and 30W Fiber Handheld Laser Marking Machines | Handheld design Fiber laser technology | $3,000 – $5,000 | 20W – 30W | 110mm x 110mm | Metals, plastics, ceramics, and more |

| Aurora Thunder Laser Marking Machine | – Fiber laser technology, Adjustable marking depth, High-speed marking, Long service life | $8,000 – $12,000 | 20W – 50W | 110mm x 110mm | Metals, plastics, ceramics, and more |

| ATOMSTACK Portable Laser Engraver | Fixed-focus laser, Bluetooth control | $200 – $300 | 5.5W | 98mm x 88mm | Wood, bamboo, leather, plastic, and more |

| ATOMSTACK X7 Pro Laser Engraver | Fixed-focus laser Large engraving area | $400 – $600 | 20W | 200mm x 200mm | Wood, bamboo, leather, plastic, and more |

| Laser Pecker 3 Deluxe Laser Engraver | Portable and compact design, AI smart engraving, Bluetooth control | $300 – $400 | 5 W | 100mm x 100mm | Wood, paper, leather, and more |